Accueil » Composite

Our customized solutions for the Composites and Plastics industry

With our high performance infrared ovens and panels,

Boost your productivity and reduce your energy costs.

Very low investment, High performance, Very limited space requirement

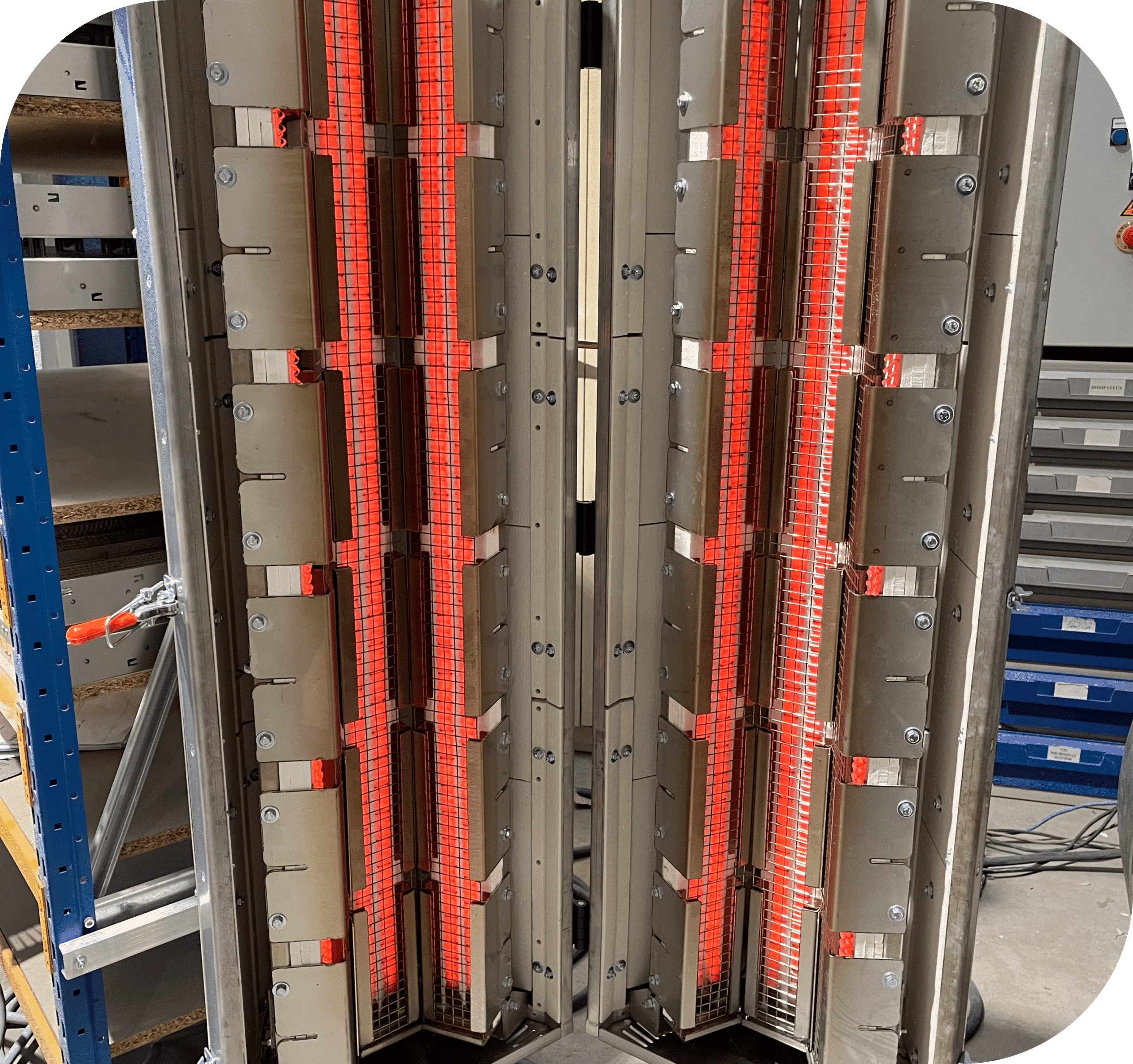

Heating of thermoplastic composites before stamping

- Heating of all types of plates and fibers of glass, carbonaramid or natural fibers

- Upgradeable oven that can heat any type of thermoplastic composite: PP, PA6, PA66, PET, PEI, PEEK, etc…

- Low inertia heater for fast and precise heating with real time power control

- Horizontal or vertical heating

- Cycle time from 30s to 120s depending on the product

- Very low energy consumption compared to convection heating

- Production or laboratory oven

Thermocompression of carpets and soundproofing

- Heating of carpets and heavy mass for vehicle interiors

- Low inertia MWI or SWI heaters for fast and accurate heating

- Single or double sided heating for cycle times from 30 to 60s

- Numerous areas with the possibility of heating local heavy mass patches

- Very low energy consumption

- Robust installation with very little maintenance

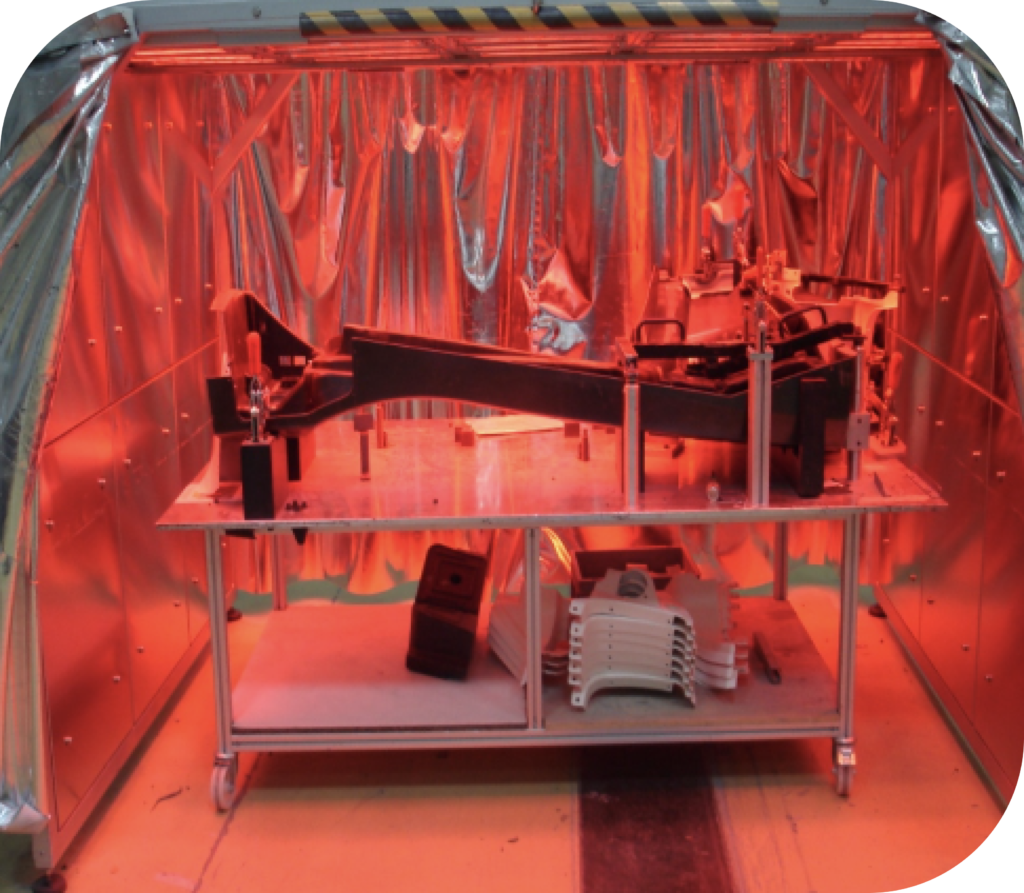

Thermoforming of Plastic Sheets

- Heating of plastic sheets of all types and thicknesses

- Low inertia IRM or IRC heaters for fast and accurate heating

- Multi-zone panel for optimal temperature control and room stretching

- Very low energy consumption. Savings of about 50% compared to long infrared ceramic wafers

- Robust installation with very little maintenance

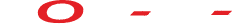

Pultrusion and extrusion reinforcement

- Continuous composite profile production

- Insertion of composite reinforcements in extruded profiles

- Fast and precise heating of one or more ribbons:

- 10 to 50 m/min in thermoplastic pultrusion

- 3 to 6 m/min in extruded profile reinforcement

- High heating efficiency on all types of thermoplastics

- Robust installation with very little maintenance

- Important accessibility by opening the ovens in full safety

Thermoplastic Filament Winding

- Realization of tanks and composite parts in 3D

- Precise and fast heating with :

- automatic adaptation to process speed variations from 0 to 20m/min

- instant start and stop

- Compact installation

- Long life span

- Low maintenance cost

Mirror welding and gluing

- Reactivation and polymerization of glue

- Adaptable to 2D and 3D parts

- Ability to save areas

- Oven does not require preheating

- Very energy efficient

- Mirror welding of plastic or composite parts

- Very fast heating (5 to 15s) without preheating

- High power density on both sides to be welded

- Ability to save areas

- Possibility of 2D or 3D radiant

- Inertia < 1 second

Polymerization and post-curing of thermoset parts

- Polymerization of 2D or 3D parts in thermosetting material.

- Post curing and desolvation of thermoset resin parts resin parts

- Instantaneous heating oven without preheating.

- Precise control of the surface temperature of the rooms.

- Small footprint.

- Energy efficient.

- Non ATEX oven with solvent residue extraction.

Find us

- ZI du mariage, 27 rue des Bruyères

- 69330 Pusignan - FRANCE

- Tel: +33 4 72 81 23 00 - Fax: +33 4 72 81 23 09

- contact@sopara.com