Accueil » Textile

Textile

SOPARA can help you to :

- Analyze your existing processes and calculate their energy efficiency.

- Test to see if an infrared solution exists for your process.

- Accompany you in the study and the realization of an industrial pilot or a production furnace

Our customized solutions for technical textiles

- With our high performance infrared ovens and panels,

- Boost your productivity and reduce your energy costs.

- Very low investment, high performance, very limited space requirements

A solution adapted to each Textile Process

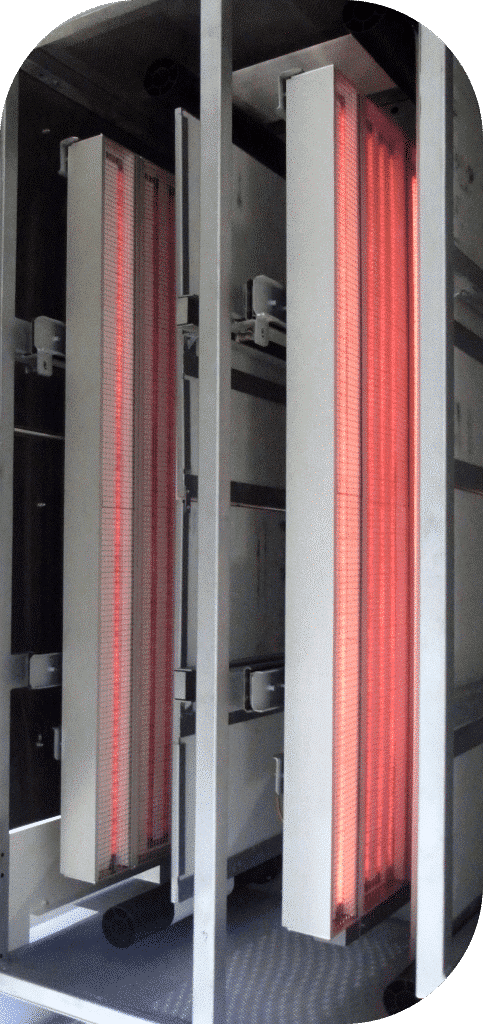

Drying and curing of water soluble coatings

- Pre-drying, drying or polymerization of water-soluble coatings on various materials (woven, non-woven, cotton, glass, synthetic fabrics, technical fibers…)

- Short- or Medium-wave Infrared High Performance Low Inertia

- Compact installation with integrated extraction

- Low energy consumption

- Easy access

Drying and curing of solvent-based coatings

- Pre-drying, drying or polymerization of solvent-based coatings (adhesives, latex, silicone, PFTE…) on various (woven, non-woven, cotton, glass, synthetic fabric, technical fibers…)

- Short- or Medium-wave Infrared High Performance Low Inertia

- Solvent drying with optimized extraction

- Precise heating management

- Low energy consumption

- Very simple maintenance

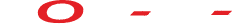

Graining, calendering, laminating

- Medium-wave Infrared High Performance Low Inertia

- Very short heating time

- High power density

- Precise heating management

- Low energy consumption

- Very simple maintenance

- Electric or gas

Gelification of PVC

- Short- or Medium-wave Infrared High Performance Low Inertia

- Very short heating time: 6 to 10 seconds

- High power density

- Surface and core heating

- Optimized plasticizer extraction

- Low energy consumption

- Very simple maintenance

Drying and sintering PTFE

- Short- or Medium-wave Infrared High Performance Low Inertia

- Fabric treatment, film or tube

- Drying and sintering in 1 pass

- Optimized solvent extraction

- Low energy consumption

- Very simple maintenance

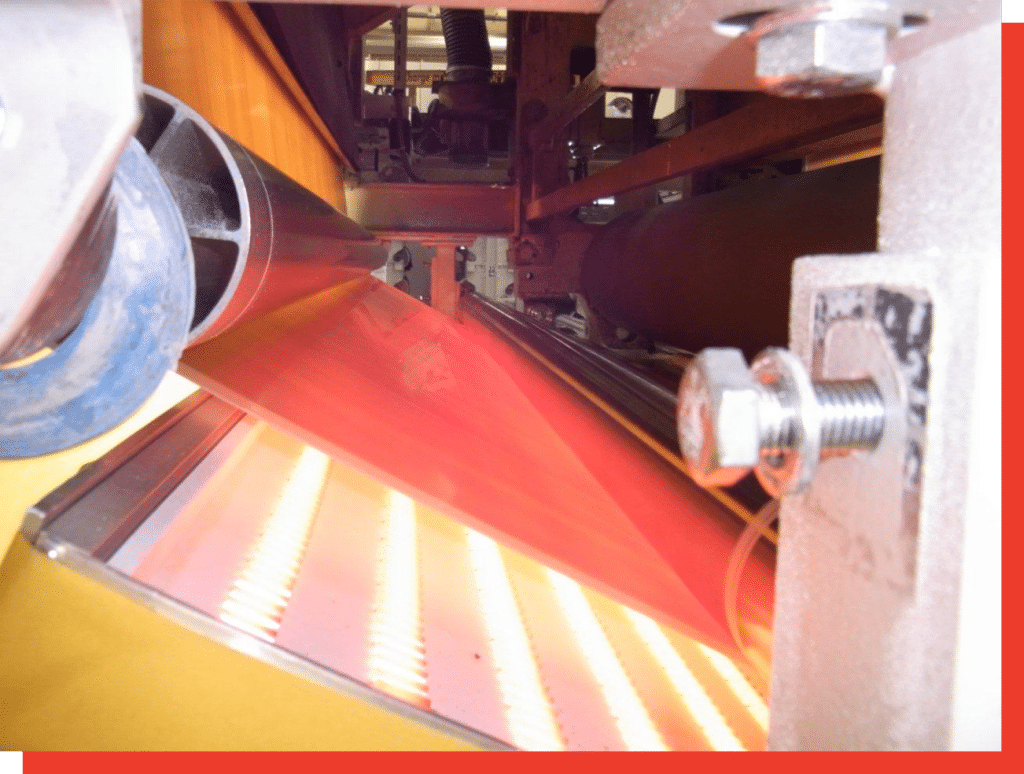

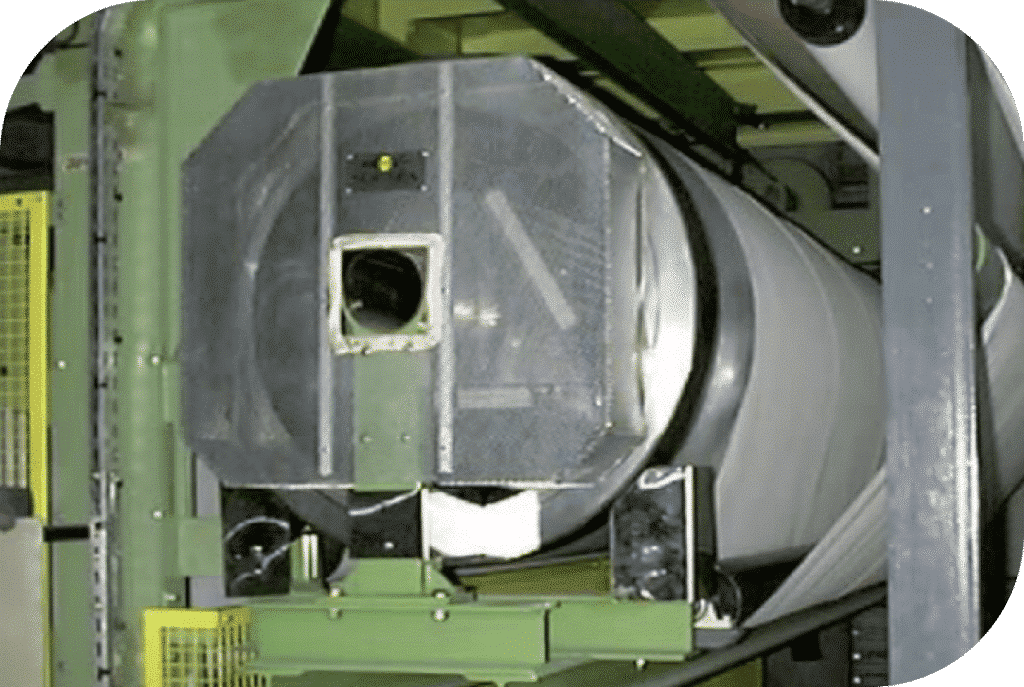

Infrared heating cylinders

- Very fast preheating: 5 to 15 minutes

- Low energy consumption

- Precise and even heating up to 300°C

- Almost no maintenance

- Optimal safety without risk of oil or steam leakage

Find us

- ZI du mariage, 27 rue des Bruyères

- 69330 Pusignan - FRANCE

- Tel: +33 4 72 81 23 00 - Fax: +33 4 72 81 23 09

- contact@sopara.com