Accueil » Paint

Liquid and powder paint

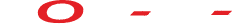

Our different applications for paint baking.

Paint curing Hydro or solvent

- On small parts with floor conveyor

- On parts moving on an overhead conveyor

- On static parts

- Compact installation

- Low energy consumption

- Automatic color matching

- Adaptation to the type of part (steel or plastic)

- Easy access and very simple maintenance

Our applications for curing liquid paint

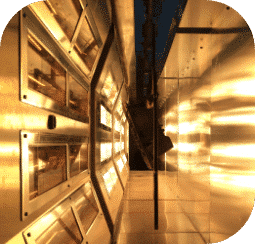

Curing of lacquers and varnishes on glass

- Compact infrared installation

- Prototyping oven and production oven

- Very fast drying and cooking: 2 to 5 minutes

- Very low energy consumption compared to hot air

- Fast and precise adjustment for every shape of part

Automotive Paint Baking

- Original equipment or bodywork touch-up.

- Very fast dust free drying

- Very low energy consumption compared to hot air

- Automatic color matching

- And possibility of automatic regulation

- Specific adaptation in size and power

- Compact installation with high power density

- Temperature measurement by infrared pyrometer and automatic regulation

Special Applications and Coil Coating

-

- Specific adaptation in size and power

- Very low energy consumption compared to hot air

- Compact installation with high power density

- Temperature measurement by infrared pyrometer and automatic regulation

Our applications for CURING powder paint

Powder coating pre-gelling

- on single piece or on coil on a scroll

- Freezing without air movement

- Compact system for upgrading existing furnaces without major investment

- Low energy consumption

- Quick start

- Very simple maintenance

Complete curing process

- on single piece or on coil on a scroll

- Freezing and cooking without air movement

- Ultra-compact installation

- Low energy consumption

- Quick start

- Very simple maintenance

Gelling of a zinc primer

- on moving parts

- on parts step by step

- Compact installation that can be integrated into an existing line

- Very fast gelling (2 to 4 minutes) and without air movement

- Automatic adaptation of the power to the weight of the pieces

- Oven with doors for very low energy consumption

Find us

- ZI du mariage, 27 rue des Bruyères

- 69330 Pusignan - FRANCE

- Tel: +33 4 72 81 23 00 - Fax: +33 4 72 81 23 09

- contact@sopara.com